Public Transport Projects

A transportation infrastructure project requires waterproofing that can hold back the Thames

Crossrail has 42 kilometres of new tunnels up to 30 metres under the streets of London. It’s the biggest infrastructure project in Europe. And that means tons of groundwater. We were there to help.

Crossrail began in 2009. Since then, we've provided customised waterproofing solutions, detailing and site support to eight major stations. Canary Wharf alone had enough groundwater to fill the equivalent of 40 Olympic-sized pools. But we're helping keep things dry with solutions like PREPRUFE® waterproofing protection, BITUTHENE® Liquid Membrane, ADCOR® hydro-expansive waterstops and more.

Once the first trains start rolling in 2018, Crossrail is expected to both reduce journey times and increase rail capacity in central London by 10 percent.

Public transport in a tough desert climate requires something you wouldn't expect: waterproofing

Fact: There are huge amounts of water sloshing around under the desert. So when the Qatar Rail Company started building their Doha Metro Network, they knew they would need waterproofing. Lots of it.

There were other considerations as well, starting with an average annual temperature of 90°F/32°C. The presence of chlorides and sulphates, which attack the reinforcement and the concrete, also complicated matters.

Plus, the construction specifications state that the stations must stay completely dry throughout a 120-year design life.

The solution is PREPRUFE® Plus waterproofing membrane — more than 1 million square metres of it. This waterproofing membrane actually bonds to the concrete. That prevents water tracking behind the waterproofing layer as well as problems caused by ground movements.

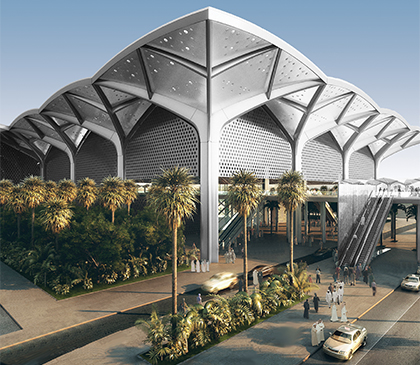

How to build — and then protect — one of the largest infrastructure projects in the Middle East

The 450 km Haramain High Speed Railway in Saudi Arabia will link the Islamic holy cities of Mecca and Medina to King Abdullah Economic City and the Red Sea coastal city of Jeddah. It's one of the largest infrastructure projects in the Middle East.

The project includes building four new stations in four years. That's a challenge even without extreme heat and desert conditions that include, oddly enough, groundwater. PREPRUFE® waterproofing membrane is the answer. It provides protection to all built elements up to levels above the water table.

The stations cover an area more than 30 times the size of London's Trafalgar Square. They will consume a staggering 300,000 square metres of PREPRUFE® 300R.