BITUTHENE® 6000 EIM

Heavy duty, preformed composite membrane combining a self-adhesive rubberised bitumen compound and a tough, puncture-resistant four-ply polyethylene laminate for electrical insulation in critical sub-structures and civil works

Product Description

BITUTHENE® 6000 EIM, whilst designed as a waterproofing membrane for concrete structures, possesses excellent electrical insulation properties. BITUTHENE® 6000 EIM is composed of a tough, cross-laminated polyethylene film, backed by a self-adhesive rubberised asphalt compound, all of which bitumen components provide high resistance to the passage of direct or alternating current.

Features

- High electrical volume resistance, volume resistivity, dielectric strength and breakdown voltage characteristics

- Cross-laminated film — provides dimensional stability, high tear strength and puncture resistance

- Cold applied — no hot works, no heating, hot mopping or torches

- Flexible — retains flexibility to accommodate ground movement, structural movements

- Controlled thickness — factory controlled uniform thickness

- Chemically-resistant

- Simple, reliable, low labour cost installation

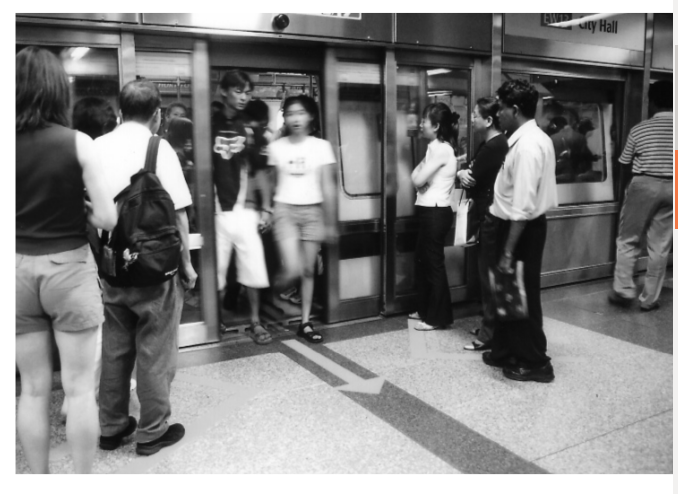

BITUTHENE® 6000 EIM is a 1.6mm membrane composed of 1.4mm of rubberised bitumen compound and a 0.2mm, 4 ply, cross-laminated polyethylene surface film, providing superior puncture and damage resistance. It is important to ensure that the membrane is not abused and damaged during installation or subsequent construction activities, to provide a continuous barrier to the passage of electrical current. The self-adhesive compound allows easy and safe cold application over large areas, without the need for torching or hot mopping of bituminous compounds. This is particularly important when work is being carried out in confined spaces or on underground projects such as Mass Transit Rail Station Platforms.

BITUTHENE® 6000 EIM is installed to prepared concrete substrates as a double layer membrane (installed in two layers with staggered laps), providing robust protection with long design life and electrical volume resistivity of >4.8 x 1014 ohm-cm required by demanding civil projects.

The thickness of the installed double layer membrane is 3.2mm.

Installation

Concrete and other masonry surfaces shall be dry (less than 10.0% moisture content), free of loose debris, sharp protrusions, honeycombing and bug holes. Concrete and masonry must be primed with a BITUTHENE® Primer. For enclosed underground areas, for safety reasons water based BITUTHENE® Primer Type C should be used, at a rate of 5 to 6 m2/litre. Porous substrates may require more than one coat of primer. Allow the primer to dry tack free before application of the membrane.

For complete instructions on the application of BITUTHENE® 6000 EIM membrane, please refer to our Work Method Statement available from your local GCP representative.

Supply

| BITUTHENE® 6000 EIM | 1m x 20m roll (20 sq m) Average net weight 40kg |

| Storage | Store upright in dry conditions below 35°C |

| BITUTHENE® Primer Type C | 20 litre pails or 200 litre drums |

| Primer Coverage | 5 - 6 m² / litre depending on method of application, surface texture, porosity and ambient temperature |

| BITUTHENE® Liquid Membrane | 5.7 litre pails |

Quality Assurance

GCP Applied Technologies is certified to ISO 9002 by TUV SUD PSB Pte Ltd.

Health and Safety

Refer to relevant Safety Data Sheets.

Specification

BITUTHENE 6000 EIM preformed membrane shall be applied onto smooth primed concrete by applying the preformed membrane, sticky side to the primed substrate, to give well rolled 50mm overlaps, laid strictly in accordance with manufacturer’s instructions and supplied by GCP. For further information, contact your local GCP representative.

Product Warranties

GCP and contractors recognised by GCP as experienced in the application of GCP products will provide warranties for qualified individual projects. Warranty periods offered are dependent on project details and complexity. Contact your local GCP representative for further details.

For assistance with working drawings for projects and additional technical advice, please contact GCP.

Performance

| Property | Typical Values | Test Method |

|---|---|---|

| Nominal Thickness* | Installed as 3.2mm thick double layer membrane 1.6mm / layer |

NA |

| Elongation | min. 300% | ASTM D412 Modified |

| Tensile Strength | min. 5000 kPa | ASTM D412 Modified |

| Volume Resistivity | min. 4.8 x 1014 ohm-cm – 3.2mm thick double layer | ASTM D-257 |

| Volume Resistance | min. 2.2 x 1013 ohm – 3.2mm thick double layer | ASTM D-257 |

| Dielectric Strength | 19.3 kV/mm – per 1.6mm membrane layer | ASTM D-149 |

| Dielectric Breakdown Voltage | 30.8 kV – per 1.6mm membrane layer | ASTM D-149 |

Typical test values represent average values from samples tested. Test methods noted may be modified.

* Nominal thickness refers to the thickness of double layer membrane with release liner removed.

gcpat.com.au | Australia customer service: 1800 855 525

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate, and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations, and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right.

BITUTHENE is a trademark, which may be registered in the United States and/or other countries, of GCP Applied Technologies, Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2025 GCP Applied Technologies, Inc. All rights reserved.

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Alpharetta, GA 30009, USA GCP Australia Pty. Ltd., 14 Colebard Street West, Archerfield, Brisbane, Queensland 4108, Australia This document is only current as of the last updated date stated below and is valid only for use in Australia. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.com.au. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2025-06-25

https://gcpat.com.au/en-gb/solutions/products/bituthene-post-applied-waterproofing/bituthene-6000-eim