BITUTHENE® 6000

Product Description

GCP BITUTHENE® 6000 is a heavy duty, preformed composite membrane combining a self-adhesive rubber/bitumen compound and a tough, puncture-resistant 4 ply polyethylene waterproof laminate for waterproofing critical sub-structures and civil works BITUTHENE® 6000 membrane is specifically designed for waterproofing structural concrete and civil works such as airports, rapid transit systems, power plants, environmental projects and earth sheltered structures. BITUTHENE® 6000 membrane may also be used in lieu of BITUTHENE®3000 membrane on basements and substructures that require extra tough waterproofing protection.

Advantages and Features

- Designed as a waterproofing speciffically capable of resisting a hydrostatic head when fully supported.

- Cross laminated HDPE — high performance 4 ply cross-laminated, HDPE carrier film with a self- adhesive rubber bitumen compound provides dimensional stability, high tear strength, puncture and impact resistance.

- Chemically bonding HDPE layers together, produces a film with greatly improved physical characteristics compared with traditional low density polyethylene films

- Single layer — simple, reliable, low labour cost with benefit of site programmed installation.

- Cold applied — no heating, self-adhesive overlaps ensure continuity.

- Chemically resistant — designed to provide effective external protection against most aggressive soils and ground water.

- Flexible — Elongation of 150% accommodates minor settlement and shrinkage movement.

- Controlled thickness — factory-made sheet eliminates site application thickness variability.

- Tanking security — combined flexible membrane and waterstop system for security.

- Specifically designed to tie into GCP PREPRUFE® Membranes and waterstops to provide a continuous waterproofing tanking system for sub-strucures and civil works.

System Components

Membrane

BITUTHENE® 6000 membrane: heavy duty, advanced, cold applied, flexible preformed waterproofing membrane. The membrane is unrolled sticky side down on to primed concrete slabs or vertical concrete faces. Continuity is achieved by overlapping 50mm and firmly rolling the joint. A guideline is printed on the membrane.

Ancillary Components (The most current Product Data and application information for these products can be found on gcpat.com) (Scott—Please supply the words (products and wording that you would like to see here)

BITUTHENE® Solvent Primer is used to prime structural concrete, masonry or wood surfaces on which BITUTHENE® waterproofing membranes are to be applied.

BITUTHENE® Solvent Primer Vertical is a bitumen-based primer in solvent, specially formulated to provide good initial adhesion of BITUTHENE® membranes to vertical applications, or in cold conditions.

BITUTHENE® Primer Type C is designed for concrete, brick and masonry substrates to which any BITUTHENE® self adhesive sheet membrane will be applied. It is also a Class 3 Type Z curing blanket for freshly placed concrete.

BITUTHENE® LIQUID MEMBRANE (LM) Two component, elastomeric, liquid applied detailing compound (NOTE—this couldn’t be found on the Australia website—need to add

Protectoboard™ used to protect all GCP liquids and sheet membranes, as well GCP waterproof membranes.

BITUSTIK™ Tape Super used as high strength waterproof jointing. It is designed to fix RAPID-DRAIN™ or PROTECTOBOARD™ to GCP waterproof membranes. BITUSTIK™ Tape Super bonds protection to membrane in critical situations and joins WATER-BAR™ PHX 230 PVC Waterstop to PREPRUFE® membranes.

Water-Bar™ waterstops used for construction and expansion joints

PREPRUFE® 300R Plus membrane pre-applied membrane for below slab and blind side waterproofing and superior tanking performance with BITUTHENE® membranes. See PREPRUFE® membrane data sheet for waterproofing under slabs and vertical reverse tanking applications

Limitations of Use

- Approved uses only include those uses specifically detailed in this product data sheet and other current product data sheets that can be found at gcpat.com.

- BITUTHENE® membranes are not intended for any other use. Contact GCP Technical Services where any other use is anticipated or intended.

- BITUTHENE® membranes are designed where in-service temperatures will not exceed 130 °F (54°C).

- Do not use BITUTHENE® Mastic to terminate BITUTHENE® membranes to PREPRUFE® pre-applied waterproofing membrabe system. Terminations to PREPRUFE® membrane should only be done with BITUTHENE® Liquid Membrane.

- BITUTHENE® membranes should never be installed through load bearing brick/blockwork walls and must be linked with the damp-proof course to prevent extrusion under load.

Safety and Handeling

Users must read and understand the product label and safety data sheet (SDS) for each system component. All users should acquaint themselves with this information prior to working with the products and follow the precautionary statements. SDSs can be obtained by contacting your local GCP representative or office, and in some cases from our web site at gcpat.com.au.

Storage

- All BITUTHENE® membranes should be stored upright

- Observe one-year shelf life and use on a first in, first out basis.

- Store in dry conditions between 4.5°C and 32°C.

- Store off ground, under tarps or otherwise protected from rain and ground moisture.

Installation

Temperature

- Apply BITUTHENE® 3000 membrane only in dry weather and when air and surface temperatures are 5°C or above.

- Where temperatures are above XXXX prime with BITUTHENE® Solvent Primer

- Where temperatures are above 5ºC but below XXXX prime with BITUTHENE® Solvent Primer Vertical

Substrate Preparation

Sloping or vertical faces shall be smooth, regular, dry and free from grease and primed with the appropriate BITUTHENE® Primer with brush or roller. Type and consumption rate of primer depends on the porosity of the surface. Allowed surface to dry completely before the application of the BITUTHENE®. Brickwork and/or blockwork shall be flush pointed or rendered to provide a smooth surface before priming.

Priming1

- All surfaces to which BITUTUENE® 6000 membrane is to be applied require priming prior to installation of the BITUTUENE® 6000 Membrane

- When temperatures exceed XXXºC apply BITUTHENE® Solvent Primer by brush or roller to the substrate at a coverage rate of 6 - 7m2/L. Allow to dry one hour or until concrete returns to original color.

- In cold weather conditions (below XXXºC apply BITUTHENE® Solvent Primer Vertical to the substrate by brush or lamb’s wool roller at a coverage rate of 6-7m2/L). Allow primer to dry one hour or until tack-free.

- Dry time may be longer in cold temperatures. Re-prime areas if contaminated by dust. If the work area is dusty, apply membrane as soon as the primer is dry. In general, priming should be limited to what can be covered within 24-hours

- Do not apply any primer directly onto any BITUTHENE® membranes.

Note 1: Where surfaces are pourous more than one coat of primer may be required. It is important to check to be sure proper BITUTHENE® adhesion is being obtained.

Membrane Application

BITUTHENE® 6000 shall be laid by peeling back the protective release paper and applying the adhesive face onto the prepared surface. A wide floor brush can be used to press across the surface of the BITUTHENE® 6000 to ensure good initial bond and exclude air. Adjacent rolls are aligned and overlapped 50mm minimum at side and ends and well rolled with a firm pressure to ensure complete adhesion and continuity between the layers. Use a linoleum roller or standard water-filled garden roller less than 760 mm wide, weighing a minimum of 34 kg when filled. Cover the face of the roller with a resilient material such as a 13 mm plastic foam or two wraps of indoor-outdoor carpet to allow the membrane to fully contact the primed substrate. Seal all T-joints and membrane terminations with BITUTHENE® Liquid Membrane (LM) by the end of the day. Damaged areas to be repaired by patching with an oversized patch applied to a clean dry surface and firmly rolled (see membrane repairs below).

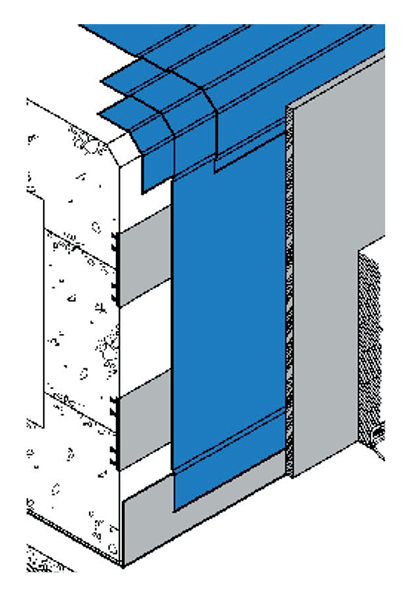

Top Terminations

Where the membrane will be terminated (on vertical walls) the exposed upper edge of the membrane must be terminated with a K Flashing or a pressure bar.

Membrane Repair

Patch tears and inadequately lapped seams with the same membrane as used on the surrounding surface. Clean the in place membrane with a damp cloth and completely dry. Slit fishmouths and repair with a patch extending 150 mm in all directions from the slit and seal edges of the patch with BITUTHENE® Liquid Membrane. Inspect the membrane thoroughly before covering and make all repairs prior to testing, covering or backfilling.

Membrane Protection

Following the application, care should be taken to prevent damage by following trades by using PROTECTBOARD™ spot bonded with Pak Adhesive or a 25mm screed as horizontal protection. Vertical faces to be protected against damage from backfilling and reinforcement by using PROTECTBOARD™ spot bonded with BITUSTIK™ Tape Super Backfill material should be compacted in layers to prevent settlement and dragging forces being transferred to the waterproofing systems.

NOTE: See PREPRUFE® data sheet for waterproofing under slabs and vertical reverse tanking applications

Supply

BITUTHENE® 6000 membrane: 1.6mm thick x 1m x 20m roll (20 sqm). Average net weight 40kg.

Ancilary Products:

- Primers: Bituthene® Solvent Primer, Bituthene® Vertical Primer, and Bituthene® Primer Type C in 20 litre pails.

- Detailing: BITUTHENE® Liquid Membrane (LM) 5.7 litre pails.

Covera

- Envelope and tie in components: Protectoboard™ BITUSTIK™ Tape Super Water-Bar™ Waterstops, PREPRUFE® 160R and 300R and PREPRUFE® 160R Plus and 300R Plus

- Terminations: K Flasiing and Pressure termination bars

Physical and Typical Performance Properties BITUTHENE® 6000 membrane

| PROPERTY | TYPICAL VALUES | TEST METHOD |

|---|---|---|

| Colour | Dark Gray / Black | N/A |

| Tensile Strength (Film Only) | 7N / mm | ASTM D-412 |

| Tape Strength | 10N / mm | ASTM D-412 |

| Elongation of Membrane (To Ultimate Failure of Rubberised Asphalt) | 150% | ASTM D-412 |

| Lap Adhesion at 23°C | 683N / mm | ASTM D-1876 |

| Cycling Over Crack at -32°C (100 Cycles) | no effect 100 cycles | ASTM C-836 |

| Puncture Resistance | 400 N | ASTM E-154 |

| Resistance to Hydrostatic Head | 60m of water | ASTM D-5385 |

| Tear Resistance | 36N / mm | ASTM D-624 |

| Permeance | 1.3ng / m3 .s.Pa | ASTM E-96 [12] |

Warranties

GCP and contractors recognised by GCP as experienced in the application of GCP products will provide warranties for individual projects. Warranty periods offered are dependent on project details and complexity. Requests for very long warranty periods may necessitate increased membrane thicknesses to ensure longevity.

Contact your local GCP representative for further details.

gcpat.com.au | Australia customer service: 1800 855 525

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate, and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations, and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right.

BITUTHENE and PREPRUFE are trademarks, which may be registered in the United States and/ or other countries, of GCP Applied Technologies, Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2025 GCP Applied Technologies, Inc. All rights reserved.

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Alpharetta, GA 30009, USA GCP Australia Pty. Ltd., 14 Colebard Street West, Archerfield, Brisbane, Queensland 4108, Australia This document is only current as of the last updated date stated below and is valid only for use in Australia. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.com.au. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2025-11-17

https://gcpat.com.au/en-gb/solutions/products/bituthene-post-applied-waterproofing/bituthene-6000