Regione Toscana set out to modernize its hospitals in Prato, Pistoia, Lucca and Massa-Carrara to offer personalized medicine and enhance the comfort of patients. For the project, architect Mario Cucinella envisioned four technologically advanced hospitals that would be integrated with a health services network across the region. Designed by Cucinella Architects, the new Apuano Hospital is based on guiding principles developed by the Ministerial Commission of Health. This team of doctors and designers brought forward health-related innovations in intensive care and interdisciplinary collaboration.

Challenge

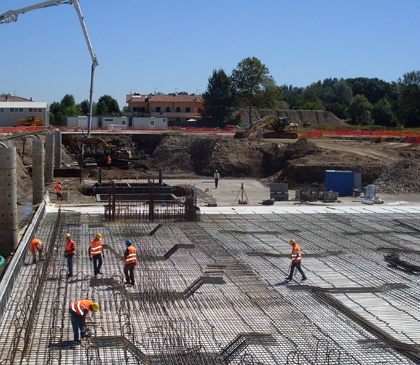

Originally, the project specified a bentonite system for waterproofing, however realizing the critical nature of the situation, general contractor ATI Astaldi-Techint-Pizzarolli and engineering team Studio Altieri S.P.A began looking for another solution.

Solution

The general contractor and engineer selected:

- The PREPRUFE® 300R pre-applied waterproofing membrane to prevent water and radon gas from permeating the below grade structure

- The BITUTHENE® 8000 post-applied waterproofing system to protect vertical walls and satisfy BS 8485:2015 standards for gas resistance

For more than 30 years, these systems have been used for high risk waterproofing protection around the world, including at many hospitals. The PREPRUFE® 300R membrane offers high performance under hydrostatic pressure. “The highest benefit was definitely the protection of water migration between the concrete surface and the membrane, due to the strong and durable bonding of the PREPRUFE® waterproofing system to the structure,” said Riccardo Prati of the waterproofing applicator firm Prati S.r.L. “In high water table situations where the risk of leaking is significant, such an effective bond provides the highest protection for the structure, and therefore piece of mind for the entire application.”

This proven waterproofing membrane provided the added benefit of helping to accelerate the construction process. “The experience I had with the PREPRUFE® 300R membrane has been very positive, especially due to the simplicity and speed of installation, which saved 20 percent on installation time,” Prati said.

GCP’s Technical Support team worked closely with Prati S.r.L during the design and construction phases, providing CAD drawings for all detailing, such as service penetrations and corner details. This helped ensure protection for all elements of the below-grade structure. Prati said, “The GCP Technical Team was very responsive, from design to the technical support onsite, and brought a high degree of professionalism.”

gcpat.com.au | Australia customer service: 1800 855 525

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Alpharetta, GA 30009, USA GCP Australia Pty. Ltd., 14 Colebard Street West, Archerfield, Brisbane, Queensland 4108, Australia This document is only current as of the last updated date stated below and is valid only for use in Australia. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.com.au. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2025-05-13

https://gcpat.com.au/en-gb/about/project-profiles/tuscany-s-apuano-hospital-chooses-preprufe-waterproofing