PREPRUFE® Seals Crossrail: One of the Most Complex Projects in the UK

London's construction of the historic Crossrail line and its stations is the biggest infrastructure project in Europe.

The project

Crossrail is one of the UK’s largest and most complex construction projects. Crossrail is expected to transform the rail network in London and the South East, reducing journey times and increasing rail capacity in central London by 10 percent.

Since work commenced in May 2009, 42 kilometers (26 miles) of new tunnels have been constructed beneath the streets of London, reaching depths of 30 metres. There will be 40 stations in total providing services for Crossrail passengers.

GCP Applied Technologies Waterproofing Solutions

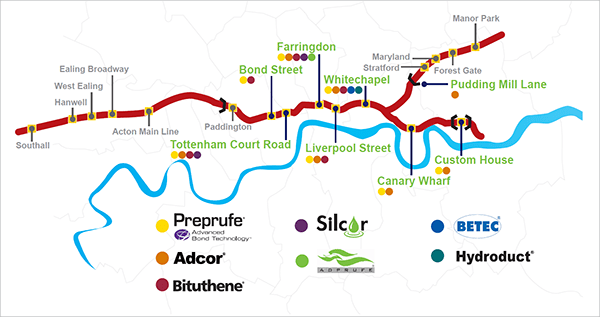

GCP is the leading supplier of waterproofing on all major Crossrail Stations. To date, GCP has provided bespoke waterproofing solutions, detailing and site support to 8 major Crossrail stations – Bond Street, Tottenham Court Road, Farringdon, Liverpool Street, Whitechapel, Pudding Mill Lane, Canary Wharf and Custom House.

Tottenham Court Road

As part of the construction of the new £1 billion Tottenham Court Road Station, more than 2000 m2 of GCP’s PREPRUFE® waterproofing membrane were chosen to deliver the high level of required watertightness.

Constructed by BBMV (a consortium of Balfour Beatty, Alpine BeMo Tunnelling, Morgan Sindall and Vinci Construction) for Transport for London, the new Crossrail station at Tottenham Court Road is the length of four football pitches and three storeys underground. With long term waterproofing performance, reliability and success at high-profile projects worldwide – PREPRUFE® offered the perfect solution to ensure waterproof protection for this.

To complete the system solution, GCP also supplied BITUTHENE® Liquid Membrane, AT System PVC waterstops, as well as ADCOR® hydro-expansive and injectable waterstops.

Liverpool Street

Over 5000 m2 of PREPRUFE® waterproofing membrane have provided exceptional water tightness, below ground protection and proven performance at Liverpool Street station.

This new £300 million development, awarded to engineers Mott Macdonald/Arup and contractor Laing O’Rourke, is located below the existing Liverpool Street and Moorgate stations and Finsbury Circus. Two new ticket halls, Broadgate and Moorgate are being constructed, as well as a 40-metre deep shaft on Blomfield Street to accommodate ventilation, electrical, mechanical and systems equipment for the station. This area known as Bloomfield box, spans over a quarter mile in one of the busiest parts of London.

PREPRUFE® was the obvious choice for confined sites, for its reputation in providing a reliable waterproofing solution, preventing water ingress through and around the base slab. Its patented ADVANCED BOND TECHNOLOGY™ enables concrete to aggressively adhere to PREPRUFE®, forming a unique intimate seal which prevents any water migration between the waterproofing and the structure, substantially reducing the risk of leaks.

Utilising an advanced acrylic surface coating developed by GCP, the PREPRUFE® membrane also simplifies the installation process by removing multiple layers and complicated detailing. Protective layers of concrete or boards are eliminated, reducing the depth of excavation and spoil, whilst the number of materials to be sourced are minimised, all accelerating the critical path of the project programme and ensuring the project was delivered on time.

Approximately 4,000 m2 of PREPRUFE® 300R/160R, 1,500 m2 of PREPRUFE® 800PA, and 250 m2 of SILCOR® liquid waterproofing were installed to provide exceptional waterproofing protection to the tunnel shafts, piled walls, base slabs and roof.

Canary Wharf

At the £500 million development of Canary Wharf Crossrail station, the 6,000 m2 application of PREPRUFE® waterproofing membrane has ensured the site remains watertight – holding back up to 10 metres of surrounding Thames dock water.

Built in the West India North Dock by Canary Wharf Contractors Limited, construction of the new station has proven a complex engineering, technical and logistical challenge. Since construction began in May 2009, some 300,000 tonnes of material have been excavated, 375,000 tonnes of concrete poured and 1,000 piles driven to extract 100 million litres of dock water – the equivalent of forty Olympic-size swimming pools.

As part of the ‘top down’ construction programme, a four-level basement was completed to a depth of 28 metres. After draining the site and constructing a deep anchored cofferdam to provide a dry work environment, the next key step on the critical path was the waterproofing for the base slab. This needed to be installed quickly and effectively, in difficult conditions, to avoid delays to the following works.

In addition to its waterproofing performance, PREPRUFE® was chosen for its ease of application and speed. The membrane is unrolled and loose laid, and can be applied even on wet substrates. The laps are self-adhesive and the whole installation can be achieved without welding or other special equipment. Once installed, no screed or other protective layers are required - the rebar installation and concreting can follow immediately.

Specified and installed at some of the most challenging waterproofing projects worldwide,PREPRUFE® proved the perfect system for lead designer Arup and contractor Expanded Piling, a subsidiary of Laing O’Rourke. No other system on the market better protects a substructure from the harmful effects of water, vapour and gas than PREPRUFE®.

For protection of the concrete joints and continuity with the piled walls, GCP also supplied a range of complementary products and systems including ADCOR® 500S and ADCOR® 550MI, to provide hydro-expansive and injectable joint protection. The cold applied BITUTHENE® Liquid Membrane and SERVITITE® AT240, a specially formulated PVC waterstop system, were also supplied to complete the project’s comprehensive waterproofing specification.

Other critical stations

As well as the above mentioned stations, GCP provided comprehensive waterproofing solutions for the other critical stations, including Bond Street, Farringdon, Whitechapel, Pudding Mill Lane and Custom House.

GCP offered bespoke waterproofing solutions providing continuity at the critical aspects of the project. A full package was delivered consisting of SILCOR® liquid waterproofing membranes, ADPRUFE® integrally waterproof concrete system and a full range of ADCOR® hydrophilic and PVC waterstops available for concrete joint protection.

Designed to link with PREPRUFE®, SILCOR® seamless waterproofing is a range of spray and hand applied liquid waterproof membranes, which provides highly durable waterproofing and structural protections without laps or complex detailing.

ADPRUFE® integrally waterproof concrete system is comprised of an innovative liquid admixture that significantly reduces both the permeability and drying shrinkage of concrete. It can be combined with GCP membranes and HYDRODUCT® cavity drain systems for enhanced protection in critical applications.

GCP’s hydrophilic waterstops' unique ability to act as a continuously active seal due to its hydrophilic properties, means it works better than conventional waterstop systems, preventing water entry through joints in concrete sub-structures.

Set for completion in 2018, the Crossrail project - sealed in PREPRUFE® pre-applied waterproofing membrane - will provide a vastly improved transport service which will benefit London, its inhabitants and visitors for generations to come.

Tags

- Contractor

- In the News

- Mass transit

- PREPRUFE®

- Subcontractor

- Waterproofing